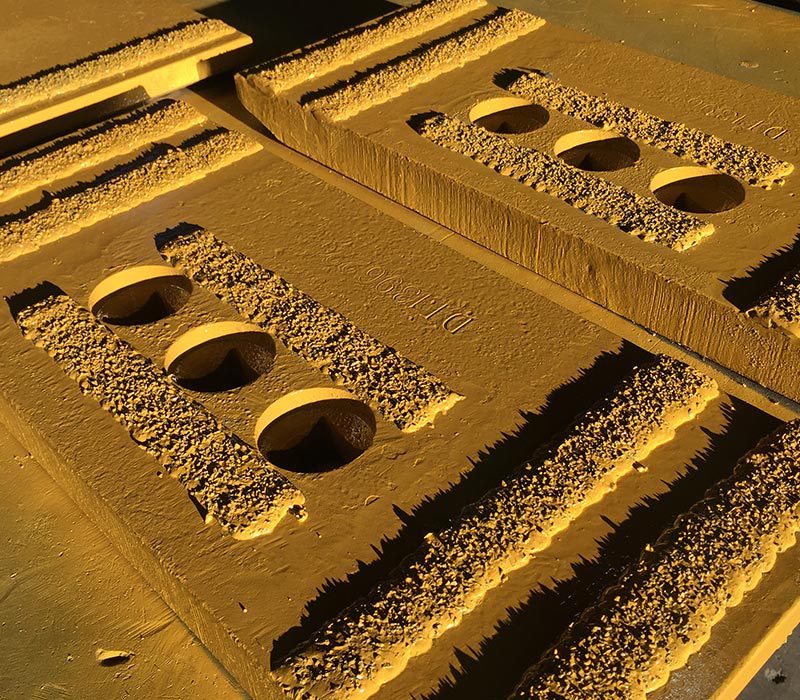

Hardfacing and Wear Materials

Hardfacing and wear materials for 1000’s of applications throughout a wide range of industries. At IMS we handle a wide range of applications due to our facility capabilities including equipment that can apply the correct hardface products needed to give extended life.

Is Carbide Welding & Hardfacing Solutions for You? Choosing the correct product for the application is a very important step to get the most benefit. By adding carbide injection process we can extend the life to wear parts by 8-10 times. At IMS time is saved due to our one stop solution.

We Provide Carbide Injection Welding & Hardfacing Services for:

Wood & Recycling

Construction

Mining & Aggregate

Material Handling

Parts & Components

Benefits of IMS Carbide Injected welding & Hardfacing

Extremely effective for high abrasion resistance, extending life far beyond original base part or product.

We select the correct product for the project or application.

Cost effective , drastically lowering your bottom line.

Installed in controlled shop environment.

Reviews

Contact Details

Innovative Mining Services Inc.

37353 Ward Road

Abbotsford, BC V3G 2K6

Hours: Monday to Friday 7:00 am - 3:30 pm

Callback Request